The Heritage Society of Essex and Middle River would like to thank Mr. Roger Dahlin for sharing his family’s history of the Essex Candle Company with us.

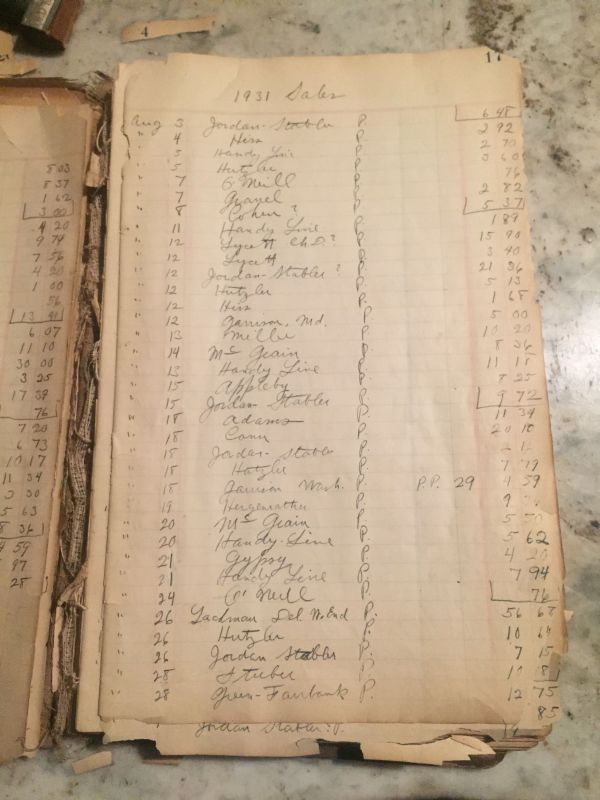

Baumgartner Collection Book #291:

Baumgartner Collection Book #291:

Essex Candle Company

Download PDF

View on archive.org

The Essex Candle Company: A Proud Tradition

By Paul M. Blitz, The Avenue News, 12/3/1987

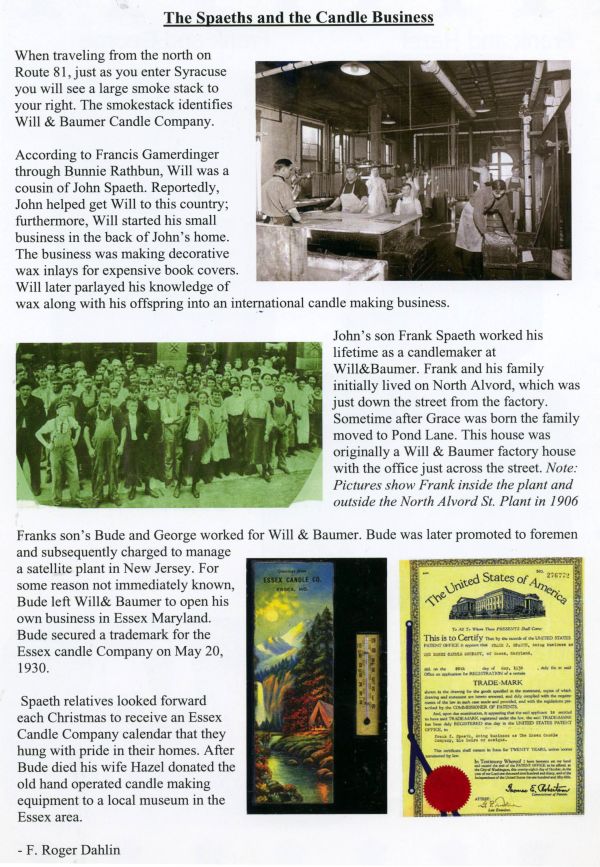

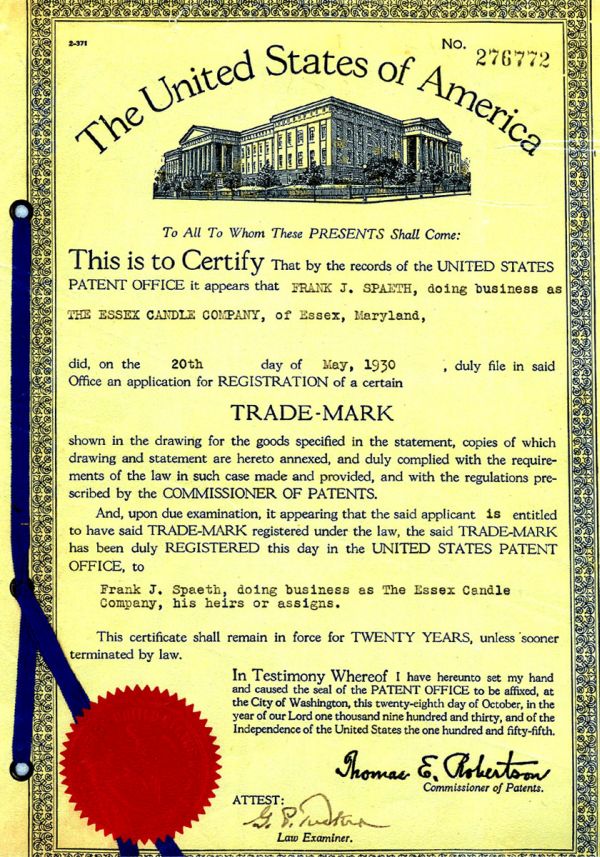

For nearly 40 years, Frank and Hazel Spaeth made candles in Essex. Located on Helena Avenue, the Essex Candle Company was in business from 1933 to 1969. Manufacturing handmade dinner candles and handmade drip-less candles which are called tapers, it was a family-owned wholesale business which sold candles in Maryland, Virginia and Washington, D.C.

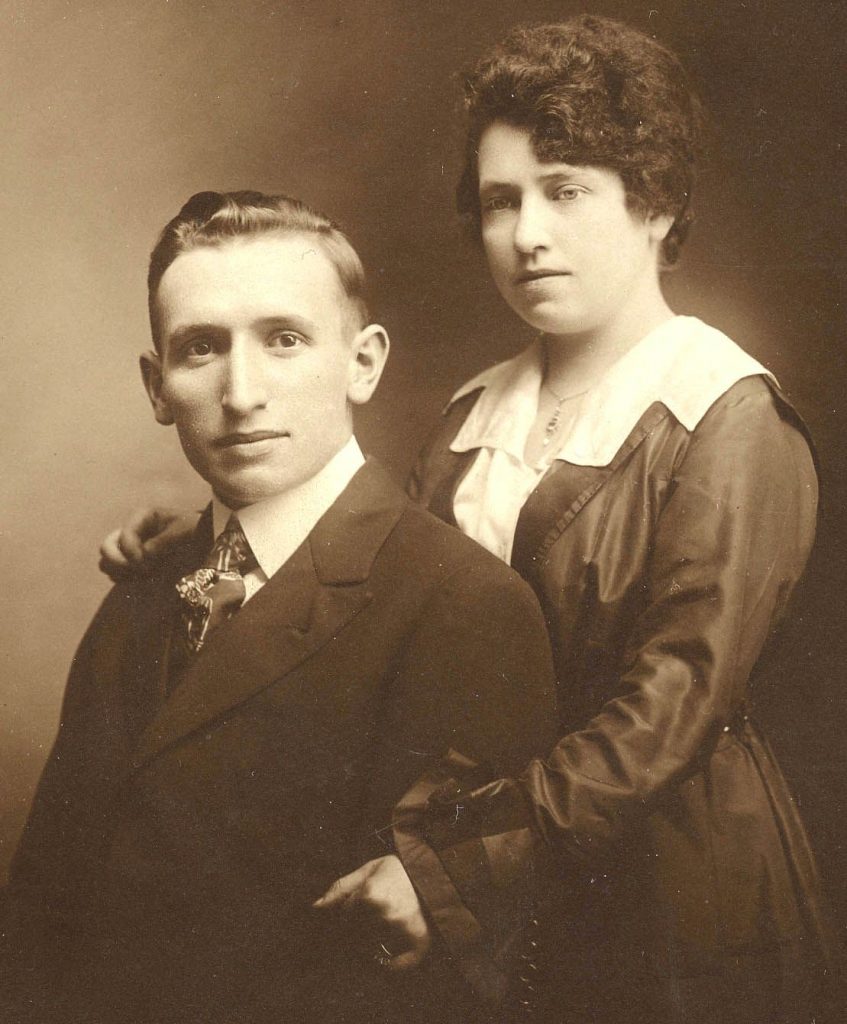

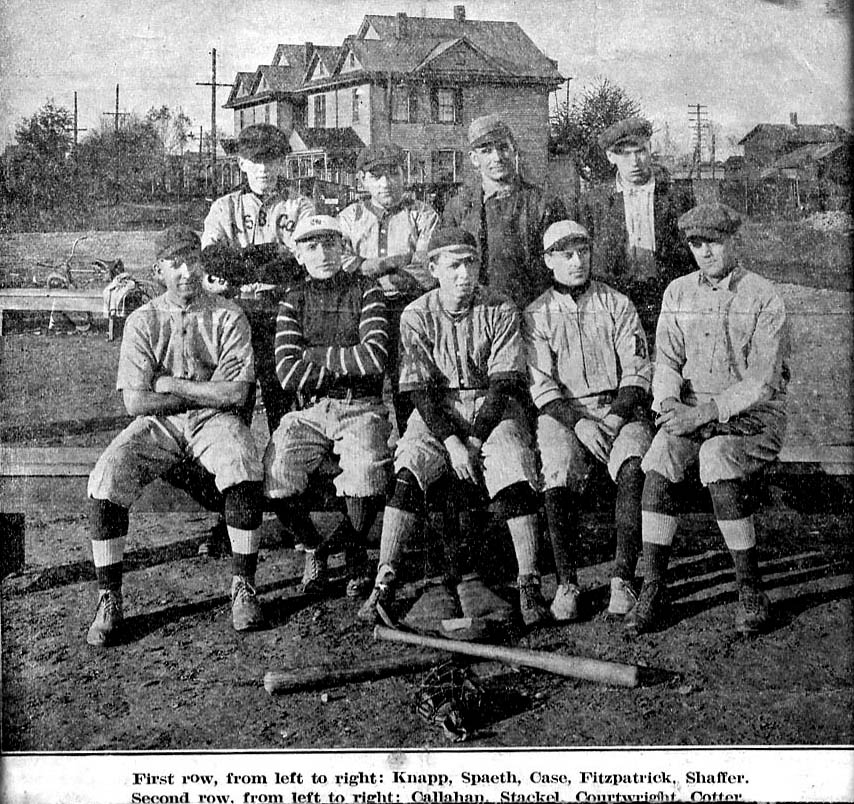

Originally from New York, Mr. Spaeth worked for the Will and Balmer Candle Company in Syracuse, New York. It was here he met his future wife Hazel. Later, he went to Newark, New Jersey to start a candle factory. In 1926, Frank came to Baltimore to work for the A. Cross Candle Co. Hazel came to Baltimore that same year and the two of them were married. Mrs. Spaeth liked Baltimore very much. “I think the people here are real friendly; I don’t think either of us wanted to go back (to New York),” she commented.

Although very few candles were sold in Essex, the Essex Candle Company was a booming business. According to Mrs. Spaeth, “We could not make them fast enough.” This was true considering some of their clientele. The Essex Candle Company supplied candles to Hutzler’s Department Store; O’Neill’s Department Store; the May Company; and the Emerson Hotel in Baltimore and the Adams Company; Garrison’s; and the Mayflower Hotel in Washington, D.C.

The only church that bought candles from the Essex Candle Company was St. John’s Lutheran Church. Mrs. Speath said that there were a number of Catholic churches in Baltimore but none of them bought candles from their shop because at that time Catholic churches could only use candles that were made from 100 per cent bees wax. This ruling was later changed.

Fred Grupp started working for the Spaeths when he was 16 years old. He was a very hard worker, employed at the Essex Candle Company after school and on weekends and Mr. and Mrs. Spaeth treated Fred like a son. Later, Fred got married and started working at the Bethlehem Steel Corporation in Sparrows Point. However, the Spaeths never lost their good worker. Fred continued working at the Essex Candle Company on weekends, around the holidays, and whenever he was needed. Many times Fred made candles all night and went to work at Bethlehem Steel the next morning. For almost 40 years, he worked for the Spaeths. Mr. Grupp gave a detailed explanation of the whole process:

“Tapers were made from hard and soft paraffin wax. Steric was added as a hardening agent. These were placed into an aluminum container sitting over two gas burners – to melt the paraffin. The melted paraffin was dipped out with a pot and put into a tank stationed under the machine.”

He continued, “Wicks were made from special woven cotton fibers and were of different thickness. Wicks were cut to different lengths. They were cut to make tapers from 6 1/2 inches to 24 inches. After cutting the wicks, they were hand-knotted on one end. The wicks were then hung on boards that were used on the machine.”

Fred added, ‘The machine had four slides that revolved over the large tank of paraffin. The slides were stopped over the center of the tank and hand lowered to a certain point to dip the wicks into the paraffin. After dipping the tapers to a certain thickness, the boards from the machine were transferred to holders on the well so they could cool (off). When the thickness of the tapers were reached, about 15/16 of an inch, they were taken off the boards, one dozen at a time, dipped into water to help cool them and put on a marble table and with measured sticks cut to proper length. They were now ready to color. The knowledge of using different pigments to make a certain color is an art in itself,” says Mr. Grupp.

“Each taper was hand-dipped into hot colored paraffin, then dropped into water to harden the color and this also put a shine on the tapers. This taper was then taken out of the water and hand dried with rags made from paraffin bags. The knot was cut off and was ready to be packed. They were rolled individually into cellophane or tissue paper, both ends twisted and put into boxes that usually held one dozen tapers. These boxes were hand-stamped with size, color, and company name then packaged for shipment,” concludes Mr. Grupp.

The average taper sold for 5 cents apiece. Mrs. Spaeth noted that today it would be too costly to produce tapers the way they made them.

In 1969, Mr. Speath died and the Essex Candle Company closed its doors. The Speaths were career partners as well as husband and wife, having built a successful business together. When her husband-partner died, Mrs. Speath closed down the candle operation because “it would not be the same without him.” To this day, she remains a widow living in the same house that they bought 40 years ago.

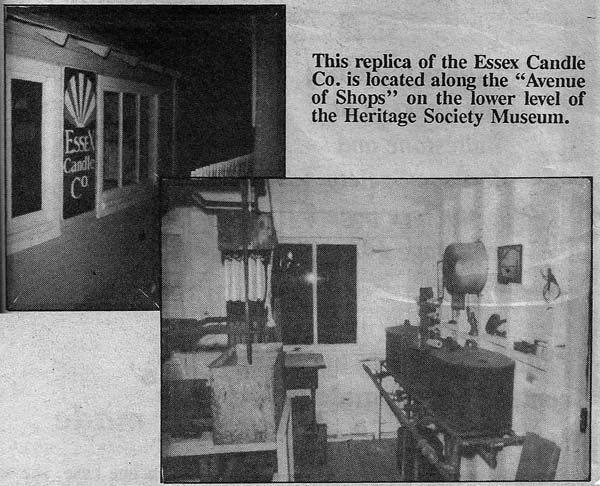

In 1975, Mrs. Spaeth donated the entire candle making operation to the Heritage Society of Essex and Middle River. A replica of the Essex Candle Company is on display at the Heritage Society Museum.

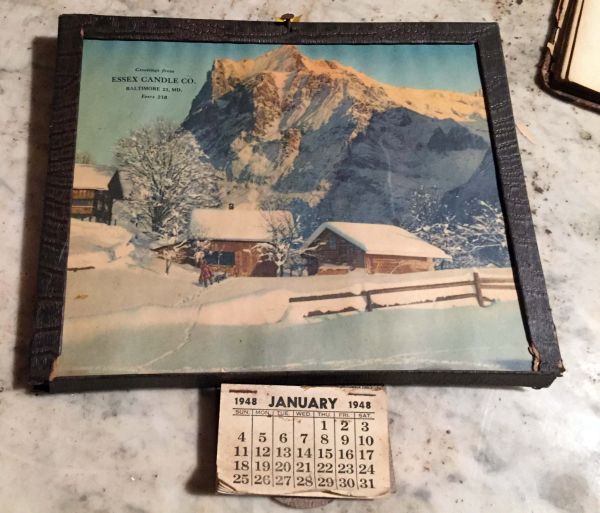

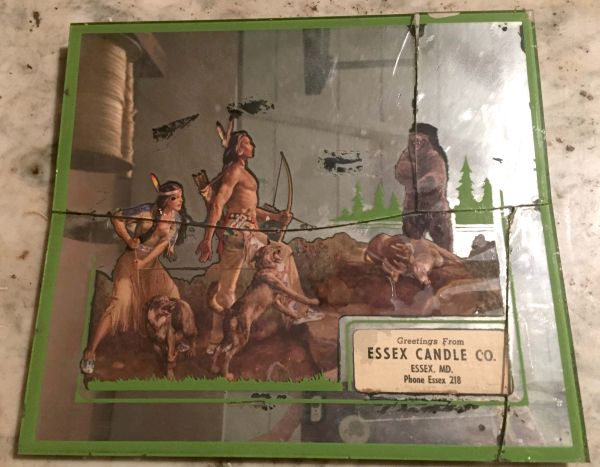

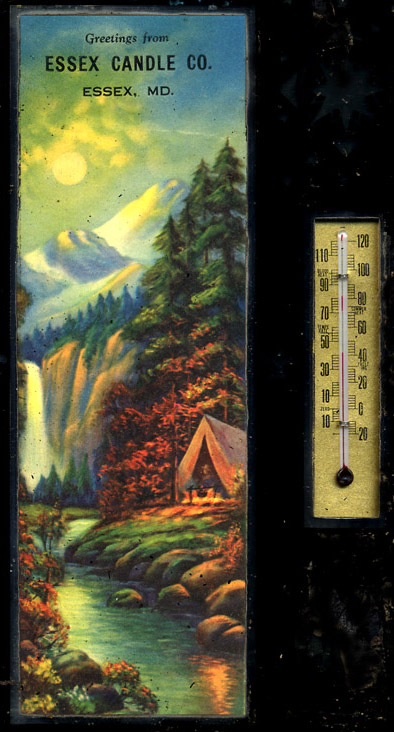

Essex Candle Co. Promotional Items

During the holidays bude would send Essex Candle Company calendars to customers and family members.

Miscellany

Related:

- Old St. Joseph’s Cemetery: A Dahlin/Spaeth Family Perspective

Roger Dahlin’s 2017 publication corrects some errors in genealogy in his 2002 research and contains considerable articles of provenance.

Read online - Spaeth Family’s Genealogy

Roger Dahlin’s original 2002 family research.

Read online or Download PDF

The article entitled ” Old St.Joseph’s Cemetery : A Dahlin/Spaeth Family Perspective” was published in 2017 . It corrects some errors in genealogy in the 2002 work identified as Spaeth Family’s Genealogy. The 2017 document contains considerable articles of provenance.

Hello Sir / Mam,

I hope that everything is going well out there and hopefully this email finds you well.

I am Adam from Slick Packages. I just came to know from one of my marketing teams that you are working for multiple products for which you require packaging and have forwarded me your information as well. As we have experienced expertise in the production of packaging.

I believe we can assist you with the best services. We are custom packaging producers, we have been working for 8 years in this industry.

We produce custom boxes in a wide range of variety for different companies and brands like CBD, Hemp, E-liquids, Vape, Vape Cartridge, Garments, Food and others.

Beside retailing and shipping boxes, we also produce boxes for annual functions. We are already working with some well-established Brands.

We are also having discounted offers with the price beating system which can help you to avoid hidden and extra charges. Some of our facilities are listed below:·

Eco-Friendly Stock and Printing.

Free Shipping·

Free Designing Support with the order·

No Custom and Hidden Charges·

No Setup Charges·

Free Templates And No Die Charges.

Standard Turnaround time is 10-12 Business Days·

Expedite Shipping will take 6-8 Business days with 15% of the total amount, which would be expedite fee. If you are interested, then please reply to this email with the specifications so that we can discuss your packaging details.

Looking forward to hearing from you.

Thank You.

Kind Regards.

Adam

Sales Manager | https://slickpackages.com | California-USA